The Digital Shop® Blog

All-Star Automotive Doubled Its Revenue In 1 Year With These 6 tricks

He has doubled his revenue in the last year, but Devin Kelley, owner of All-Star Automotive in Columbia, Missouri, says there’s no magic involved in the way he runs his shop – just hard work and consistency.

“I’m human, just like the rest of us,” Devin told Tom Dorsey, host of The Digital Shop Talk Radio. “I don’t consider myself any magical shop owner or anything like that. I’m no genius. I just see a lot of good stuff, and I try to write it down. I’ve got great coaches like Paul Marsh at ATI and Bill Connor there at AutoVitals, and all you guys at AutoVitals are amazing. So, just be a sponge, and there’s great stuff out there.”

As Tom likes to say, “if you want to be successful, do what successful people do.” Here are a few things Devin and his All-Star Automotive crew have implemented to run an efficient and money-making auto repair shop.

1. Create a culture of performance

Devin recently took over at All-Star Automotive. One of the first things he did was evaluate how the crew was working together.

“We had a lot of really high performers,” he told Tom in episode 45. “I was extremely blessed to have some amazing people on this team. It’s just incredible what they do. We also had some people that weren’t as high performers, and they were affecting the high performers quite a bit.”

Once he’d seen how everyone was working together, he began to focus on the culture of the shop. It was apparent pretty quickly those lower performers weren’t going to fit into the repair shop he was trying to create.

The staff of All-Star Automotive.

“In some ways naturally, and in some ways not, the culture ended up with more of the high performers on board, so we needed less people overall,” Devin said.

Now he just lets his high performers do their thing, and so far, it has created some incredible results.

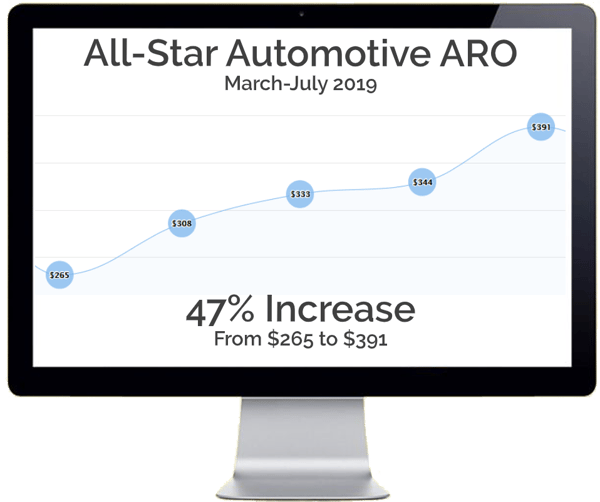

All-Star Automotive saw a 47% increase in ARO in just 5 months' time.

All-Star Automotive saw a 47% increase in ARO in just 5 months' time.

2. Lots of two-way communication

Frequent team meetings and listening to his crew have also been staples during the transition.

“A lot of it comes down to the communication that we have,” Devin said. “We do bi-weekly shop meetings, and we talk about things much more frequently than that, of course, but in a formal way, we do shop meetings every other week.”

During these meetings, he has an agenda he runs through, which he has found to be extremely productive. It is also at those meetings he receives a bunch of beneficial information from his crew.

“I am always excited to hear different people’s perspectives,” he said. “I may not always agree, or I might not even know if I agree or not in the beginning, I’m a really analytical person, so I just like perspective.”

Allowing for comfortable two-way communication also allows Devin to implement changes without overwhelming his auto repair techs. Listening with an open mind and taking feedback to heart has allowed for some amazing changes to take place, he said.

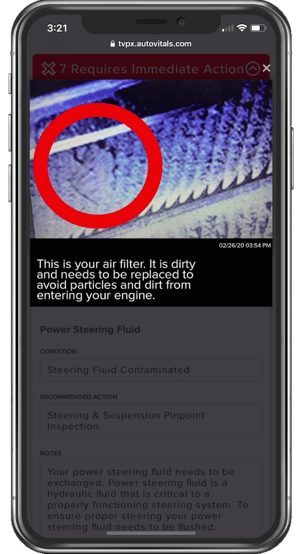

Recently, he decided to implement a few things in the digital vehicle inspection (DVI); specifically, he wanted notes on the pictures techs were taking during the vehicle inspection. Devin brought this to his team in a meeting, and with their input, they compromised and came up with something that works for everyone.

“We came up with a concept that was more simple, that more came from them, and I know in my mind it may not get the same results, at least initially, but because the buy-in is so high, they’re implementing like crazy,” Devin shared. “It’s already having a positive impact, so that’s something really important that I try to keep in mind.”

3. Monitor (don’t micromanage) the data

Devin has also realized that while monitoring data is essential, there is a difference between monitoring data and micromanaging it.

“I try not to look at everything daily because that’s micromanaging, and nobody likes to be micromanaged,” he said. “We don’t even like to micromanage ourselves if we really think about it. It’s good to look back from a little bit further away sometimes, in that I just mean, I’m not checking all of our key performance indicators every single day unless I am diagnosing a problem like a technician.”

.png?width=436&name=New%20Project%20(14).png)

Some of the KPIs he does monitor are average repair order (ARO), hours per repair order, gross profit margin, and productivity.

“I think productivity is something that I look at pretty frequently,” Devin said. “Weekly, absolutely, and actually, daily, because we try to track those things in live time.”

The reason he watches productivity as carefully as he does is to identify things that happened during the week - whether they were circumstantial or things that were or weren’t within their control. When he can name those events, it is easier to see the whole picture.

“We’ve had certain key performance indicators that have just taken off like a rocket, and then I’ll see some volatility, and so it’s important to look at it in the big picture and figure out what changes can we make that are going to be sustainable in a positive direction?” he said.

He also makes sure to bring these KPIs to his bi-weekly team meetings to celebrate the wins, set goals to continue to raise the bar, and give his team a target to shoot for.

“It does help them to have that target number just to know what good looks like,” Devin told Tom. “We don’t want to just be running 100 miles an hour not knowing, ‘Are we running fast? Are we running slow?’ There’s nothing to compare it too.”

4. Don’t flood the shop engine

There is always room for improvement, and Devin has a long list of things he would like to implement, but he has learned over time that changing too many things at once doesn’t get you results.

“I’ve changed and implemented so much this year that I’m trying to be very careful about what I implement and when,” Devin said. “Years past, I’ve been guilty of being way too progressive and changing things so fast that nobody knew what was left and what was right and what I was expecting and what we’re all supposed to be doing. So, using that experience, this year, I’ve tried to be really careful with how much I implement and how much is new.”

When he does make a change to the process, he works hard with his crew to make sure it is consistent.

“When we implement something new, for instance, we were just talking last week about adding notes to pictures,” Devin shared with Tom. “It’s something that I’ll do a lot of follow-up on. Anything that’s going to become a habit, we have to do it for a while before it can become a habit, and an important part of that is my follow-up in talking about our expectations and our performance. I think watching it for a while to make sure it’s consistent is very telling.”

5. Ask for motorist feedback and respond to it

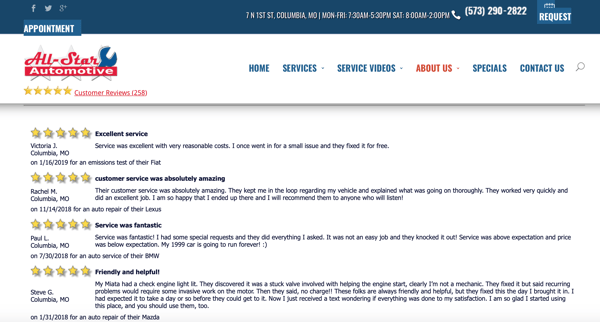

Customer feedback is an important and sometimes scary part of running an auto repair shop, but Devin makes sure he is getting feedback from as many vehicle owners as possible.

He uses software to send a text message to motorists three days after service asking them for their level of satisfaction. The vehicle owners who respond, often either want to rant and rave about their service or complain about a bad experience. Those reviews are critical, according to Devin, but the reviews that aren’t as extreme are often the most enlightening.

“What’s nice about the follow-up though is I get the in-between,” Devin said. “Because that in-between really mad and really happy is some really good stuff.”

Devin responds to every review he receives, and while he admits it can sometimes be a lot to keep up with, he believes it is an integral part of the business.

A small sample of reviews at All-Star Automotive

“For a long time, I’d feel very, very stressed about a bad review,” Devin said. “I still take them extremely seriously, good or bad, and I’ve found some peace in being accepting of a one-star review. We’re human, everybody is, and people understand that when they see it.”

He sees those negative reviews as an opening.

“I feel like any one-star review that we get is an opportunity for us to be transparent and show people who we deal with adversity and how we really want to help,” he said.

6. Work on the bench

As the All-Star crew continues to build an automotive shop that is firing on all cylinders, the idea of expansion is always on Devin’s mind.

Yet, before he would even consider opening up another location, he would need to have one thing in place, a full bench.

“What I mean by that is that the guys sitting on the sidelines who are saying, ‘I’m just waiting on a call from All-Star Automotive for when it’s my time to step up and join the team.’ If we had enough people on that bench, I feel like there’s a lot of what we do that’s really scalable. But none of it would be possible without the type of people that we have currently. So, if we get enough people on the bench that fit our culture, it would make another location a lot more feasible.”

Want to hear more from Devin?

- Listen to his full Digital Shop Talk Radio episode here

- Learn how to use quick wins to get staff buy-in in episode 69

- Devin talks to Tom in episode 28 about getting more value from your Digital Vehicle Inspections

How to contact Devin and All-Star Automotive:

Read On

Processes: The Key to Success (Even When Your Entire Shop Has COVID)

Disaster struck Levon Arnold’s shop Long Arm Mechanics, in Garden City, Idaho, late last year when...It's All Fun and Games ... Then You See This Shop's Success

Bill Rimmer and Ashley Payne from Cooper Lake Automotive joined Tom Dorsey, host of The Digital...'Level-up' Your Repair Shop With Protractor, AutoVitals Integration

Do you want to take your auto repair shop to the next level? Jodi Knepper, owner of Lee Myles Auto...Posts by Topic

- Digital Shop (47)

- auto repair shop (44)

- automotive shop management software (31)

- Auto Shop (29)

- Autovitals (29)

- DVI (29)

- shop management (25)

- workflow (18)

- Digital Marketing (17)

- BCP (16)

- CRM (15)

- auto repair shop marketing (15)

- Staff Buy-In (14)

- Best Practice (13)

- aro (13)

- Consistency (11)

- Digital Vehicle Inspection (11)

- Process Change (11)

- Tech (11)

- service advisor (11)

- COVID-19 (10)

- KPIs (10)

- Shop Culture (10)

- Websites (10)

- AutoVitals News (8)

- Integration (8)

- Website (8)

- automotive shop software (8)

- Announcement (7)

- Automotive Technician (7)

- Press Release (7)

- Partners (6)

- auto repair marketing company (6)

- auto repair shop SEO (6)

- New Features (5)

- auto repair services (5)

- best auto repair software (5)

- Coaching (4)

- Customer Reviews (4)

- Paperless (4)

- Reviews (4)

- auto shop management (4)

- multishop (4)

- smartflow (4)

- Automotive Technician Shortage (3)

- DRIVE Shops (3)

- Digital Shop Conference (3)

- Industry Events (3)

- Meineke (3)

- NAPA (3)

- Shop-Ware (3)

- auto parts inventory (3)

- auto shop efficiency (3)

- automotive repair invoice app (3)

- creative (3)

- drop off (3)

- training (3)

- web based auto repair software (3)

- Automotive text messaging (2)

- Bookkeeping for auto repair shops (2)

- Case Study (2)

- POS (2)

- Picture Edits (2)

- Protractor (2)

- Recruiting (2)

- RepairPal (2)

- TeE-Times (2)

- The Digital Shop Talk Radio (2)

- inventory management (2)

- loyalty (2)

- Auto mechanic interview questions (1)

- BayIQ (1)

- Building a Bench (1)

- Campaign Manager (1)

- Canned Jobs (1)

- Community (1)

- GMB (1)

- Guided Inspection (1)

- Hiring (1)

- Interview (1)

- MRT (1)

- Motorist Approval (1)

- Q&A (1)

- Remote Work (1)

- Service Writer (1)

- TVP (1)

- Tekmetric (1)

- The Digital Shop Summit (1)

- Who's in our shop? (1)

- auto parts (1)

- auto repair shop financing (1)

- best auto repair shop websites (1)

- estimate (1)

- financing (1)

- inflation (1)

- marketing plan (1)

- parts catalog (1)

- pricing (1)

- retention (1)

- script (1)

- social media (1)

- social media marketing (1)