The Digital Shop® Blog

4 Ways to Add Value to Your Digital Vehicle Inspections (DVI)

In a world filled with digital shops, digital vehicle inspections (DVI) are essential; but essential doesn’t have to mean boring. Neil Daly, owner of Oceanside Motorsports (OMS) in Oceanside California, has found four ways to keep his technicians fresh and inspections streamlined and personalized for customers.

In a world filled with digital shops, digital vehicle inspections (DVI) are essential; but essential doesn’t have to mean boring. Neil Daly, owner of Oceanside Motorsports (OMS) in Oceanside California, has found four ways to keep his technicians fresh and inspections streamlined and personalized for customers.

1. Vehicle Inspection Clinic

Neil’s shop understands the importance of vehicle inspections, and in an effort to keep his auto techs fresh, he organized an inspection clinic where all his techs inspected the same car.

Once the motor vehicle inspections were complete, Neil went through each DVI with his entire team. This allowed them to see where they had made mistakes or where others were doing things differently.

Learning from each other also allowed Neil and his team to recognize areas where they needed to improve individually.

“On mine,” Neil said, “I missed that it had a cracked belt because I had looked at the main belt from one side, but the other guys caught the AC belt on the bottom. [The inspection clinic] made it so I was like, ‘Wow, I missed that, I am not going to do that again.’”

Neil and his techs also realized the average picture count varied widely. Some inspections had as few as seven or eight photos while the more comprehensive vehicle inspections had two dozen or more.

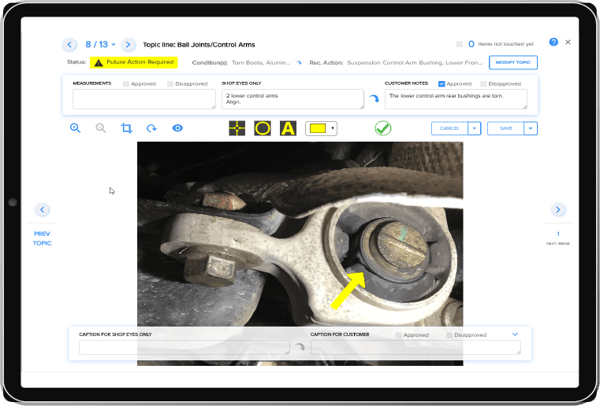

With color-coded circles, arrows and notes, the motorist can easily tell what needs fixing (red), what repairs can wait until next time (yellow), and areas of their vehicle in perfect health (green).

At the end of the clinic, Neil built two estimates, one using the “worst” inspection and one based on the “best.”

The difference was staggering, Neil said.

“It came out to be a $6,000 difference,” he said. “It showed our technicians that a little bit of extra time in the inspection – which it did take the guy about ten minutes longer to do it right, still under our 30-minute mark – but an extra ten minutes really gave a better service to the customer and allowed us the possibility of having some more work.”

Surprising Results

Two results Neil hadn’t expected also became evident during the clinic:

- The technician who did the best vehicle inspection wasn’t going over the average inspection time as he thought.

“We actually thought on average [the tech] was taking too long to do an inspection,” Neil said. “But when we went in and actually looked at the average time for inspection, he’s totally within what we expect.” - Techs weren’t looking at the customer view of the inspection report very often.

The staff at OMS realized looking at the customer-facing view of the vehicle inspection report helped to make their inspections better, Neil said.

Neil told Tom that he planned on continuing these inspection clinics not only to keep his techs fresh but also to continue to bring his team closer and closer to giving the same inspections.

“I’m sure it got us closer,” Neil told Tom. “I’ll still get a different inspection from everybody if we were to put the same car through the shop again, but it would be a little bit better.”

2. Standardized motor vehicle inspection toolkits

In addition to running inspection clinics, Neil is also streamlining inspections using a standardized inspection kit.

“We all made sure that we had the same measurement tools,” he said. “We have the same brake pad measuring tool, the same thing for the tire tread depth.”

He even makes sure to provide his new techs with a little kit that has all the inspection tools they will need.

Neil says the standardized kit serves two purposes. First, the customers can become familiar with the tools and understand what they see in pictures. Second, the techs and customers can easily compare the images and readings from an old annual vehicle inspection to a new one.

“You can show the old pictures from the last inspection next to the new one,” Neil said. “That’s super valuable. It allows us to see that percentage go up if it’s going to over time and all that good stuff.”

However, it isn’t just the measurement tools that Neil has made consistent across the shop; he has also jimmy-rigged a solution to the always-present question of “How do you get sufficient light to take inspection photos?”

For Neil and his team, it just took a snap light and a few magnets, and now all of the inspection photos are well-lit.

Neil Daly explains this trick he used to add more light to his pictures.

3. Comprehensive Inspections: personalized for customers, fun for the crew

When it comes to DVI, Neil and his crew want to make sure they are keeping cars roadworthy and building customer relationships at the same time.

That can be as simple as taking a photo of something the customer fixed last time and letting them know how well it’s working, or taking a picture or making a note of a cool license plate frame or a modification the owner is proud of.

OMS has also recently started checking the registration stickers on license plates.

“That’s part of the service provided at check-in,” Neil said. “If that’s expired, and some people don’t even realize, we’re going to be around to catch it.”

Another personal touch Neil uses at his shop is the technician pictures.

By incorporating a little personality into their pictures, Neil's team stands out in a big way

“We encourage the guys to make it a little bit more personable,” he said.

But it doesn’t just have to end at a nice photo. Neil has dreams of customizing those photos for different holidays or events. One example he mentioned to Tom was wearing a turkey hat for Thanksgiving. He believes those special touches create a bond with customers and create loyalty to a business.

“We haven’t gotten that far yet, but I think that’d be a cool personal touch that people would appreciate.”

4. Going the extra mile

Neil acknowledged that with digital vehicle inspections, it is so easy to say “not on this car,” or “not for this guy,” or “they’re not going to buy anything.” Still, those are often the people who end up using the information from the inspection to make repairs or improvements.

Here are a few more tips and tricks that Oceanside Motorsports uses to make sure their Digital Inspections are valuable for the shop and their customers:

-

- Keep old parts to show a good and bad version:

A valuable trick OMS uses is taking photos of common problems they see in the shop, so they can share a visual of what things should look like.

“We took an engine mount that was collapsed and then took one that was good and put them side by side,” Neil said. “…We just took a picture so you could see the actual difference between what it’s supposed to be and what it was, and that was really huge for selling those.”

Keeping old parts to show those differences helps, he said.

- Keep old parts to show a good and bad version:

-

- Use a borescope for those hard-to-see places:

At the shop, Neil and his techs will use a borescope to take pictures of things that are hard to get to.

Recently, he was diagnosing a water pump on an Audi, and since they had to remove the throttle body to determine where the leak was, they used the borescope to take a photo of the intake valve.

“[The intake valve] was covered in carbon, so we took pictures, put it in the inspection, recommended the carbon cleanup, and that was really easy for the advisor to sell,” he said.

- Use a borescope for those hard-to-see places:

-

- Perfect your inspection handoff:

Neil’s shop uses AutoVitals for their digital vehicle inspection software, and Neil has practiced workflow automation with his team to make the inspection process efficient and seamless.

The first portion of their vehicle inspection report consists of check-in and all the mileage-based concerns. OMS advisors have conversations with the customer about previous maintenance and fill out this portion before the car even goes back to the technicians.

“The advisor actually starts the inspection on his tablet and does the walk around,” Neil said about his shop. “We take pictures of the wheels, and [the advisor] recommends anything based on mileage. If they’ve done it, we put it into their record.”

Once the advisor has completed that portion, they close out and pass the inspection on to the tech.

“It took a little while to get that handoff seamless – going from the advisor to the technician – but we’ve got it down now,” Neil said. “He then closes it, gets it to the tech, and they’ve already got all that stuff filled out for him.”

- Perfect your inspection handoff:

-

- Build on prior inspections:

In an effort to make comprehensive vehicle inspections consistent, Oceanside Motorsports has been using a feature of AutoVitals DVI, which allows them to see and edit old inspections.

They realized it was better to look at the inspections as an ongoing thing, instead of a new one every time, and now they will never go back.

“It makes it easier,” said Neil. “You might not have to take new pictures of if it’s a car we saw a month ago, and a lot of the conditions are the same.”

- Build on prior inspections:

Want to hear more from Neil?

Listen to his first Digital Shop Talk Radio Episode #17 here

How to contact Neil and Oceanside Motorsports:

Read On

The Processes You Need to go Fully Paperless

Customers stepping up to the service counter at Downtown Automotive, in Nelson, British Columbia,...Diagnosing Shop Performance with the Business Control Panel (BCP)

You spend your days diagnosing vehicles, but did you know you should also be applying that...Deep Dive into TeE-Times

The AutoVitals digital shop solution is packed with benefits. Still, sometimes those benefits can...Posts by Topic

- Digital Shop (47)

- auto repair shop (44)

- automotive shop management software (31)

- Auto Shop (29)

- Autovitals (29)

- DVI (29)

- shop management (25)

- workflow (18)

- Digital Marketing (17)

- BCP (16)

- CRM (15)

- auto repair shop marketing (15)

- Staff Buy-In (14)

- Best Practice (13)

- aro (13)

- Consistency (11)

- Digital Vehicle Inspection (11)

- Process Change (11)

- Tech (11)

- service advisor (11)

- COVID-19 (10)

- KPIs (10)

- Shop Culture (10)

- Websites (10)

- AutoVitals News (8)

- Integration (8)

- Website (8)

- automotive shop software (8)

- Announcement (7)

- Automotive Technician (7)

- Press Release (7)

- Partners (6)

- auto repair marketing company (6)

- auto repair shop SEO (6)

- New Features (5)

- auto repair services (5)

- best auto repair software (5)

- Coaching (4)

- Customer Reviews (4)

- Paperless (4)

- Reviews (4)

- auto shop management (4)

- multishop (4)

- smartflow (4)

- Automotive Technician Shortage (3)

- DRIVE Shops (3)

- Digital Shop Conference (3)

- Industry Events (3)

- Meineke (3)

- NAPA (3)

- Shop-Ware (3)

- auto parts inventory (3)

- auto shop efficiency (3)

- automotive repair invoice app (3)

- creative (3)

- drop off (3)

- training (3)

- web based auto repair software (3)

- Automotive text messaging (2)

- Bookkeeping for auto repair shops (2)

- Case Study (2)

- POS (2)

- Picture Edits (2)

- Protractor (2)

- Recruiting (2)

- RepairPal (2)

- TeE-Times (2)

- The Digital Shop Talk Radio (2)

- inventory management (2)

- loyalty (2)

- Auto mechanic interview questions (1)

- BayIQ (1)

- Building a Bench (1)

- Campaign Manager (1)

- Canned Jobs (1)

- Community (1)

- GMB (1)

- Guided Inspection (1)

- Hiring (1)

- Interview (1)

- MRT (1)

- Motorist Approval (1)

- Q&A (1)

- Remote Work (1)

- Service Writer (1)

- TVP (1)

- Tekmetric (1)

- The Digital Shop Summit (1)

- Who's in our shop? (1)

- auto parts (1)

- auto repair shop financing (1)

- best auto repair shop websites (1)

- estimate (1)

- financing (1)

- inflation (1)

- marketing plan (1)

- parts catalog (1)

- pricing (1)

- retention (1)

- script (1)

- social media (1)

- social media marketing (1)