The Digital Shop® Blog

Babcock Auto Care: Pt. 2

This is part two in a series about Babcock Auto Care. Find part one here.

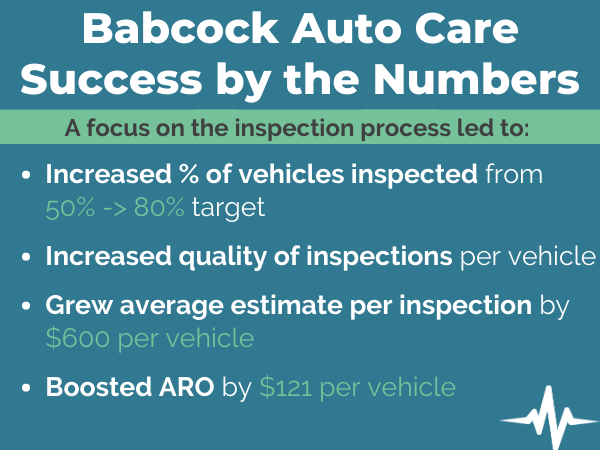

Babcock Auto Care spent six weeks focusing on its inspection process, and the results were incredible.

But their story doesn’t end there.

Hidden benefits

In addition to the increase in ARO and average estimate per inspection, ATI Coach Mike Bennett pointed out several other benefits the Babcock Auto Care crew saw.

1. Deferred work = CRM connections down the line

“Listen, you want to write a repair and do all this work with an inspection today and have it be one and done,” Mike told host Tom Dorsey and AutoVitals founder Uwe Kleinschmidt on a recent episode of The Digital Shop® Talk Radio.

But, if you only sell 50% of the work, now that information can go into the marketing system as deferred work, and now we have the chance to let our CRM system make the reconnections and start to bring those people back, he said.

“There’s the money in the bank,” he said. “Not only were we able to weather (COVID-19) and actually see such an increase in the revenue base that kept us very healthy in a catastrophic - a generationally catastrophic period of time in business - but we’ve also then further increased our potential going down the road. That’s one of the key pieces. That’s the unintended positive consequence that ends up happening here.”

2. Conversion rate changes

Babcock Auto Care also found their conversion rates of recommended to accepted work changed pretty dramatically. While they had a historic conversion of 49%, which they were incredibly proud of, the crew soon realized they weren’t inspecting or recommending as much as they should’ve.

After increasing the inspection rate to 80%, they found a reduction in their conversion rate but an increase in their ARO. A healthy range for conversion is 25%-35% to ensure you are recommending enough and applying successful sales strategies at the counter.

3. Increasing observational recommendations

Another unintended benefit was a significant increase in observational recommendations.

Babcock Auto Care went from an average of 7-9 recommendations to 15 or 16.

“The acceleration ... is the addition of the service counter really following the due diligence of looking at the service history against Carfax against today’s mileage, and so forth,” Mike said.

It is a testament to how well the front and back of Babcock Auto Care were working together.

“Each one understanding their responsibility in the process,” Mike shared. “This is how you end up with that estimated value, these recommendations, and ultimately, all the things we saw as a victory.”

Keys to success

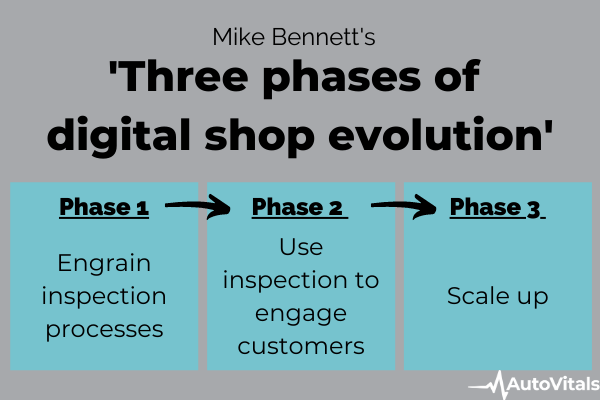

One of the biggest catalysts to the shop's success was their shop leaders, in addition to the three-phase process.

The Babcock Auto Care crew.

“It’s nuts,” he said. “It really is. That’s how successful they’ve been, and that’s a top-down leadership thing.”

Mike even took it a step further. It might have been because of Babcock’s location so close to a world-renowned medical facility, but Mike, Tom, and Uwe used several medical-related analogies to describe the importance of shops using best-practices.

Mike is familiar with auto shops fearing customers will be upset if they present them with too many issues about their vehicles.

“Listen, I would be thrilled if my doctor didn’t tell me I needed a colonoscopy, but I’m going to be less thrilled if I end up having a problem down the road,” Mike said.

Vehicle owners are the same. If you don’t tell them about the transmission service or leak repair they need now, and it turns into them needing a new transmission, people aren’t going to be happy.

“I may not be mad at you during visit one, and I may not even realize I should be mad at you for visit two when it cost me eight times more, but the reality is as a professional, that’s our responsibility,” Mike said. “We dropped the ball there if that occurs 100%.”

Uwe agreed with Mike, saying it is all about making the right decision.

“A small piece of a big pie is still bigger than a big piece of a very small pie,” he said. “Our job is to identify what’s the right size pie, and when do you eat what piece. It doesn’t need to be eaten in one visit.”

Uwe also pointed out by providing an estimate for all of the work your car needs sends a message to motorists that your shop is more of a “car care program instead of a fix everything now and then come back when my next problem happens.”

Once established, vehicle owners seem to understand the shop is working to take care of their vehicle, and they should follow the recommendations given.

Once again, Mike used a healthcare example to illustrate his point.

“You know with dental you get your teeth checked every six months; it’s not like you wait to have a cavity or a sore gum to go back to your doctor,” he said. “You’re on an annual physical with your doctor too.”

It should also be the case with cars.

Changing minds

One of the concerns Mike heard from the front-counter staff at Babcock Auto Care when implementing phase one of the digital shop evolution was they knew their customers. Their customers didn’t want all of the information inspections provide.

Listen to the Babcock Auto Care story, here.

Now, they realize their error in thinking.

“The proof is in the pudding,” Mike said. “When they completed the phase one transition when they really got themselves to the point where their inspection and recommendations speak for themselves, they now have a product that engages the customer. I mean, how many times have we presented that to Mr. Jones? The guy that denied it four times before when it was presented in such a way that it sounded like an optional ‘ Do you want sprinkles on your ice cream?’ as opposed to ‘That’s a problem.’”

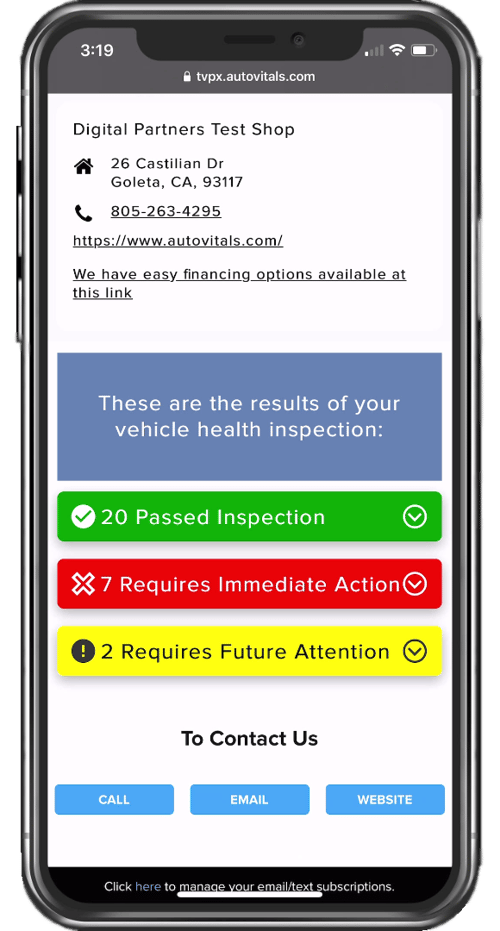

Besides providing visual proof for the motorists through photos and videos, service advisors have a different mindset and a different tact when talking about what they’re seeing and why it’s a problem.

A motorist view of the DVI.

A motorist view of the DVI.

“It became much more natural to the service advisors,” Mike said. “For the most part, customers felt more educated and were more comfortable with giving the okay than they had previously been.”

Having the DVI allowed the service counter and the customer to feel like they were on the same side. For those motorists who said no to work, it wasn’t as firm a no, but instead a ‘let’s look at it next visit.’

All of this boils down to operational excellence, says Mike.

“Operational excellence is predicated 100% on consistency to best practice, and the more that we can do that, the more value to our customers,” he said. “We think we’re in the customer service business; we are. That’s a result of what we do very professionally and correctly. It should not be the driving force, nor a decision if we do what we’re supposed to do correctly.”

Getting technician buy-in

Babcock’s story is super impressive, but how can you implement some of their success at your shop?

Start with technician buy-in.

“We played a six-week game,” Mike told Tom and Uwe. “We put some targets out there, said ‘Trust us it’s going to be worth your while.’ We got enough conversation going about best practices and who we are as a shop and our obligation to be consistent with our customers.”

Then came the other half, Mike said. The ‘What’s in it for me?’ portion.

Mike stressed that shop leaders should include real-world examples of how labor hours per ticket change with an increased number of recommendations or increased number of inspections.

“If everybody’s doing their part of the process, there’s a natural result,” Mike said. “The result ends up being the payback down the food chain, so to speak.”

Mike started talking with Babcock Auto Care in October 2019 about increasing their inspection rate and inspections sent from 50% to 80%.

“You can see it is self-perpetuating and driving right now,” he said. “We honestly haven’t had to have this conversation in almost a year. Success breeds the willingness and the interest in doing more of that thing. That’s where I think when talking about those three phases of evolution, you’ve got to get past that implementation phase.”

Mike acknowledged many shops have half-a-toe in and half-a-toe out, but when a shop becomes fully vested, the transition to phase two is natural, and then it smoothly shifts to phase three.

“This has been an odd year where we maybe haven’t necessarily targeted increased revenues,” Mike said. “Some shops have been able to do that. Some markets have been very badly hit. But we’ve got great cases like [Babcock Auto Care] where literally they’ve been able to weather the storm with what would otherwise have devastated. In this case, it kept them right on pace, and I think that’s quite honestly because of the full acceptance and implementation of those three phases.”

Watch the full episode here:

Read On

A Case Worth Studying: Babcock Auto Care

Babcock Auto Care deserves a mic drop. Just ask Mike Bennett, ATI Coach, who shared a case study...More Than Just Repair: These Shops Care About Cars and Community

It’s no secret that Fred Gestwicki, owner of Fix-it With Fred, and Russ Crosby, owner of Russ’s...Workflow Management Made Simple

Greg Masewic, a Meineke multi-shop owner, and our Digital Shop® Talk Radio hosts, Bill and Uwe,...Posts by Topic

- Digital Shop (47)

- auto repair shop (44)

- automotive shop management software (31)

- Auto Shop (29)

- Autovitals (29)

- DVI (29)

- shop management (25)

- workflow (18)

- Digital Marketing (17)

- BCP (16)

- CRM (15)

- auto repair shop marketing (15)

- Staff Buy-In (14)

- Best Practice (13)

- aro (13)

- Consistency (11)

- Digital Vehicle Inspection (11)

- Process Change (11)

- Tech (11)

- service advisor (11)

- COVID-19 (10)

- KPIs (10)

- Shop Culture (10)

- Websites (10)

- AutoVitals News (8)

- Integration (8)

- Website (8)

- automotive shop software (8)

- Announcement (7)

- Automotive Technician (7)

- Press Release (7)

- Partners (6)

- auto repair marketing company (6)

- auto repair shop SEO (6)

- New Features (5)

- auto repair services (5)

- best auto repair software (5)

- Coaching (4)

- Customer Reviews (4)

- Paperless (4)

- Reviews (4)

- auto shop management (4)

- multishop (4)

- smartflow (4)

- Automotive Technician Shortage (3)

- DRIVE Shops (3)

- Digital Shop Conference (3)

- Industry Events (3)

- Meineke (3)

- NAPA (3)

- Shop-Ware (3)

- auto parts inventory (3)

- auto shop efficiency (3)

- automotive repair invoice app (3)

- creative (3)

- drop off (3)

- training (3)

- web based auto repair software (3)

- Automotive text messaging (2)

- Bookkeeping for auto repair shops (2)

- POS (2)

- Picture Edits (2)

- Protractor (2)

- Recruiting (2)

- RepairPal (2)

- TeE-Times (2)

- The Digital Shop Talk Radio (2)

- inventory management (2)

- loyalty (2)

- Auto mechanic interview questions (1)

- BayIQ (1)

- Building a Bench (1)

- Campaign Manager (1)

- Canned Jobs (1)

- Case Study (1)

- Community (1)

- GMB (1)

- Guided Inspection (1)

- Hiring (1)

- Interview (1)

- MRT (1)

- Motorist Approval (1)

- Q&A (1)

- Remote Work (1)

- Service Writer (1)

- TVP (1)

- Tekmetric (1)

- The Digital Shop Summit (1)

- Who's in our shop? (1)

- auto parts (1)

- auto repair shop financing (1)

- best auto repair shop websites (1)

- estimate (1)

- financing (1)

- inflation (1)

- marketing plan (1)

- parts catalog (1)

- pricing (1)

- retention (1)

- script (1)

- social media (1)

- social media marketing (1)