The Digital Shop® Blog

Customer Confusion and Service Disputes? It Might Be Your Process, Not Your People

Even top shops get one-star reviews. The culprit usually isn’t effort—it’s an inconsistent process. In a high-trust, high-stakes business like auto repair, miscommunication or surprise costs can quickly erode confidence. Here’s how to optimize shop processes to deliver a consistent, transparent, and dispute-free experience.

- When Good Teams Still Get Bad Reviews

- Digitize Your Process to Bring Clarity

- Standardization Builds Trust, One Visit at a Time

- Train the Process, Not Just the People

- From Friction to Confidence: The Payoff of Process

When Good Teams Still Get Bad Reviews

It’s frustrating to read a one-star review when you know your team went above and beyond. But many service complaints stem from the same underlying issues: inconsistent communication, unclear estimates, or customers feeling surprised at the end of their visit. None of these are necessarily caused by a lack of effort; they’re symptoms of an outdated workflow.

Customer confusion usually creeps in when:

- Inspections aren’t done consistently

- Recommendations lack visuals or clarity

- Status updates are infrequent or unclear

- Estimates change after the fact

- Advisors and technicians aren’t aligned

Even top-performing teams can struggle when there’s no standard process guiding communication.

Digitize Your Process to Bring Clarity

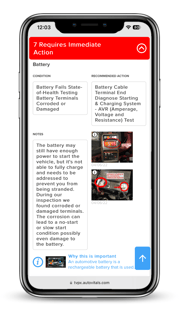

Digital Vehicle Inspections (DVIs) are among the most effective tools for reducing auto repair service disputes because they eliminate confusion and increase customer trust. DVIs show your customer —not just tell them —what needs immediate attention with their vehicle. AutoVitals’ DVI empowers shops to clearly communicate repair needs using images, educational videos, and canned notes that explain the “what” and the “why” behind every recommendation.

One of the most common sources of customer disputes involves alleged vehicle damage, such as claims of chipped paint or scratches discovered after service. With a comprehensive DVI that includes walk-around images, your shop has timestamped proof showing the vehicle’s condition before any work begins. This visual record protects your team from unfounded claims and reassures customers that their vehicle was handled with care.

The same approach applies to services and repairs: before-and-after photos of replaced parts or completed work help demonstrate transparency and craftsmanship. These visuals give customers confidence that issues were resolved thoroughly and prevent future disputes before they arise.

Customers can review everything on their own time, removing the ambiguity from the conversation and reducing back-and-forth questions. And because every inspection is stored and accessible, both customers and service advisors can reference previous visits, building trust over time.

Standardization Builds Trust, One Visit at a Time

Consistency builds confidence. When every visit follows a clear, repeatable process, from check-in to pickup, customers know what to expect, and your team delivers with fewer surprises. Standardization ensures that no matter who’s on shift, every customer receives the same level of service and communication, creating reliability that drives repeat business.

A standardized workflow keeps everyone aligned. With clear procedures in place, technicians and service advisors stay in sync, updates flow in real time, and common issues like missed approvals or unclear notes fade away. AutoVitals workflow features, such as Shop Eyes Only notes, let your team communicate privately within the workflow, keeping sensitive details or context in-house while ensuring everyone involved in the job stays informed.

When advisors and technicians aren’t aligned, even simple jobs can become confusing—for both the team and the customer. A technician may complete an inspection or repair step without the advisor realizing it, leading to missed updates or inaccurate promise times. This disconnect can cause customers to feel like they’re being left in the dark, especially if the advisor doesn’t have full visibility into the vehicle’s status.

AutoVitals closes that gap with Internal Chat and real-time technician progress tracking. Advisors can see each technician’s status as work moves through the workflow, helping them meet promise times and provide accurate updates without constant interruptions or guesswork. Internal Chat enables quick, documented communication between advisors and technicians, ensuring questions are resolved efficiently and details don’t get lost in translation.

With these tools, every team member stays informed, every promise time stays realistic, and every customer interaction is backed by confidence and clarity.

Train the Process, Not Just the People

When every person works a little differently, minor inconsistencies can add up, but things like missed steps can be avoided with proper training. Building a training program that focuses on proven processes will help those lessons stick. Process training builds confidence by helping your staff know what’s expected of them, so they can focus on doing great work instead of guessing what comes next.

As mentioned above, a defined workflow gives your team a shared roadmap. It turns good habits into standard practice, speeds up onboarding, and ensures quality doesn’t depend on who’s working that day. That’s where AutoVitals supports your investment in people. Inspection Guided Mode walks technicians through each step so nothing gets overlooked, while features like smart workflows and Shop Eyes Only notes keep teams aligned and communication seamless. Together, thorough training, a standardized process, and the right tools create a shop that runs smoothly and delivers a consistent, trusted experience every time.

From Friction to Confidence: The Payoff of Process

The payoff of digitizing and standardizing your shop processes goes far beyond fewer disputes. It leads to:

- Faster approval times.

- Higher average repair orders.

- Improved customer retention and repeat visits.

- A more confident, empowered team.

- Fewer bottlenecks and wasted time.

AutoVitals is built for shops that are serious about delivering transparent, consistent, and profitable auto repair experiences. From digital inspections and workflow consistency to CRM and marketing, our solutions help auto shops grow with clarity and confidence. Learn how we help shops like yours turn process chaos into customer confidence. Schedule a demo today.

Read On

10 Things to Consider When Upgrading Your Shop Management System

Upgrading your shop management system (SMS) is a decision that can impact every area of your...How to Manage an Increased Car Count in Your Auto Repair Shop

As the cost of cars increases, car owners are prioritizing and investing in vehicle longevity. This...5 Ways to Improve Your Shop’s 2024 Technician Recruiting Strategy

The automotive industry isn’t just facing a technician shortage—they’re facing a technician crisis....Posts by Topic

- Digital Shop (47)

- auto repair shop (44)

- automotive shop management software (31)

- Auto Shop (29)

- Autovitals (29)

- DVI (29)

- shop management (25)

- workflow (18)

- Digital Marketing (17)

- BCP (16)

- CRM (15)

- auto repair shop marketing (15)

- Staff Buy-In (14)

- Best Practice (13)

- aro (13)

- Consistency (11)

- Digital Vehicle Inspection (11)

- Process Change (11)

- Tech (11)

- service advisor (11)

- COVID-19 (10)

- KPIs (10)

- Shop Culture (10)

- Websites (10)

- AutoVitals News (8)

- Integration (8)

- Website (8)

- automotive shop software (8)

- Announcement (7)

- Automotive Technician (7)

- Press Release (7)

- Partners (6)

- auto repair marketing company (6)

- auto repair shop SEO (6)

- New Features (5)

- auto repair services (5)

- best auto repair software (5)

- Coaching (4)

- Customer Reviews (4)

- Paperless (4)

- Reviews (4)

- auto shop management (4)

- multishop (4)

- smartflow (4)

- Automotive Technician Shortage (3)

- DRIVE Shops (3)

- Digital Shop Conference (3)

- Industry Events (3)

- Meineke (3)

- NAPA (3)

- Shop-Ware (3)

- auto parts inventory (3)

- auto shop efficiency (3)

- automotive repair invoice app (3)

- creative (3)

- drop off (3)

- training (3)

- web based auto repair software (3)

- Automotive text messaging (2)

- Bookkeeping for auto repair shops (2)

- Case Study (2)

- POS (2)

- Picture Edits (2)

- Protractor (2)

- Recruiting (2)

- RepairPal (2)

- TeE-Times (2)

- The Digital Shop Talk Radio (2)

- inventory management (2)

- loyalty (2)

- Auto mechanic interview questions (1)

- BayIQ (1)

- Building a Bench (1)

- Campaign Manager (1)

- Canned Jobs (1)

- Community (1)

- GMB (1)

- Guided Inspection (1)

- Hiring (1)

- Interview (1)

- MRT (1)

- Motorist Approval (1)

- Q&A (1)

- Remote Work (1)

- Service Writer (1)

- TVP (1)

- Tekmetric (1)

- The Digital Shop Summit (1)

- Who's in our shop? (1)

- auto parts (1)

- auto repair shop financing (1)

- best auto repair shop websites (1)

- estimate (1)

- financing (1)

- inflation (1)

- marketing plan (1)

- parts catalog (1)

- pricing (1)

- retention (1)

- script (1)

- social media (1)

- social media marketing (1)